By Allison Rosenthal, Bruce Kaiser, and Beverly Perkins

As the previous essays amply demonstrate, Proctor’s creation of bronze sculptures was not a solitary pursuit, but rather a collaboration with the foundries he employed. Castings of the same work can vary greatly in quality depending on the casting technique, degree of surface finishing, and patination.[1] These variations can be characteristic of certain foundries, but they also occur in bronzes known to be cast by the same foundries, which can give clues about when a sculpture was cast or about personnel changes within the foundry.[2]

The foundry that cast a bronze sculpture is therefore a key part of the artwork’s provenance. Since January 2014, the Buffalo Bill Center of the West has been collaborating with Bruker Elemental and the Proctor Foundation on a project that aims to identify elemental patterns among the alloys, or compositions, of Proctor’s bronze sculptures. Testing using X-ray fluorescence (XRF) spectroscopy [3] has been conducted on 122 of Proctor’s lifetime castings throughout the United States and Canada.[4] This testing allows us to draw a connection between the alloy composition of a bronze and the foundry that cast it, and then use this information in conjunction with other analytical techniques—including visual inspection and archival research—to extrapolate previously unknown provenance information about many of Proctor’s sculptures.

We have been using XRF spectroscopy to analyze Proctor’s bronzes in a two-step process. By first exciting the photons of each element, a step we call detailed elemental presence analysis, we have identified the elements present in the alloy and patina of each tested bronze. We are then able to compare the relative amounts of copper, zinc, tin, lead, and iron in the second step, which we call relative elemental concentration studies.[5] This process is a pioneering approach in the field of XRF analysis, and in using these methods, we have been able to identify trends that are characteristic of certain foundries over time. Visual inspection has also allowed us to learn how a bronze was cast and then to confirm many of our hypotheses by finding casting records in foundry archives. We are using this information to deduce the foundry histories of some of Proctor’s unidentified bronzes, and we have noticed especially distinct trends among the alloys of bronzes cast by four of the foundries Proctor worked with: Gorham Co. Founders, the Roman Bronze Works, Eugene Gargani & Sons, and Jno. Williams, Inc. Bronze Foundry.

Gorham Co. Founders

Gorham Co. Founders of Providence, Rhode Island, started off as a jewelry business in 1818 and evolved into a silver manufacturing company. By 1865 it had become the world’s largest manufacturer of fine silver. In the 1880s, the company started casting ecclesiastical furnishings and other decorative works in bronze using sand casting, a method its workers were already employing to cast silver. Within the next decade they began casting bronze sculpture.[6]

With the exception of a failed attempt to create a lost-wax casting facility in 1907, Gorham used two techniques to cast bronze sculpture: sand casting and its own technique, called the plaster mold process.[7]

Plate 12.1 — Alexander Phimister Proctor

Fawn (first model) (Gorham, detail – underside), 1914

Bronze. The white residue indicates a plaster mold casting. R.W. Norton Art Gallery, Shreveport, Louisiana

Plate 2.2 — Alexander Phimister Proctor

Fawn (first model) (Gorham, detail – underside), 1888

Bronze. The residue of sand from the sand core, as well as a smoother overall surface, is characteristic of sand casting. Buffalo Bill Center of the West, Cody, Wyoming. Gift of A. Phimister Proctor Museum with special thanks to Sandy and Sally Church. 4.08.08

Both processes would have begun in a similar fashion: the artist would make a model of his sculpture out of wax or clay and then have it cast as a plaster model. This plaster model would begin the sculptor’s collaboration with the foundry. If the sculpture was to be sand-cast, the founder would build up a piece mold out of hard-packed sand; this negative mold could then be removed in pieces and assembled. The founder used the piece mold to make another copy of the model out of sand and shaved down this copy to create a casting core. Next, the founder baked the negative mold and core with pins inside to hold the core just the right distance away from the mold. Molten bronze was then poured into the space between the mold and core, after which the mold and core were removed, and the bronze was chased and most likely patinated. Gorham’s plaster mold process was similar to sand casting in many ways, except that the piece mold and core were created out of plaster mixed with asbestos rather than hard-packed sand.[8]

Gorham did not note which casting method was used in recording a job in its ledgers; indeed, the founders wrote surprisingly little on the specifics of their plaster mold process. However, we can differentiate between Gorham’s two casting methods by visually inspecting the underside of a sculpture’s base. [ Plate 12.1 and Plate 12.2] If a bronze sculpture is known to have been cast by Gorham, it is possible to tell a sand from a plaster mold casting by the white residue left by the plaster core on the base’s underside. We used XRF spectroscopy to test fifty-three known Gorham sculptures, a sample size larger than that of any other foundry included in the study. Sixteen of those sculptures are plaster mold castings, and thirty-seven are sand castings.

Gorham also frequently created bronze models for sculptures when its founders were producing an edition.[9] They referred to those models as “metal patterns.”[10] Ten of the fifty-three tested Gorham sculptures are metal patterns, and all of these are sand castings.

The conclusions we have drawn through analysis of the alloys of the tested sculptures are based on their ratios of copper photons to zinc photons and the ratios of copper photons to tin photons. Copper is the main element of a bronze alloy, and the remainder of the alloy is composed of varying proportions of tin, zinc, and lead, with traces of other metals. A bronze alloy is preferable to pure copper for casting because its melting point is much lower, it is less porous than pure copper, and it cools and contracts less rapidly. The addition of zinc, tin, and lead lowers an alloy’s overall cost, lowers its melting point, and allows it to be cast with greater fluidity, which allows for crisper surface detail.[11]

Our analysis indicates that different foundries used different alloy formulations, and the degree of consistency with which they used them varied from foundry to foundry. While Proctor had his bronzes cast at Gorham from 1909 to 1930, the company appears to have used a few different alloy formulations. It used two alloy formulations exclusively for sand casting, one with comparatively more zinc and less tin, and the other with comparatively less zinc and more tin. The company also had a third alloy formulation, with little to no zinc, which it used for both sand and plaster mold casting.

These data suggest that Gorham’s mysterious plaster mold casting process was much more precise than its sand-casting process. A 1952 Gorham publication titled “Statuary to Electronics via Plaster Molding” illuminates the need for a specific alloy formulation in the plaster mold casting process:

The casting in plaster of solid solution alloys and others, for that matter, requires special attention to gating, feeding, etc., because the mold material is an excellent insulator, causing the casting to have a much slower rate of solidification than if cast in sand. The permeability of plaster is very low; therefore it is essential that all precautions possible be taken to provide adequate venting for the free passage of gases which may be in the metal or generated within the mold at pouring. . . . Metal pouring temperatures are very critical and require close control. The typical pouring range is between 1275 and 1375°F; however, each casting has its own best pouring temperature whether in sand or plaster, but pin pointing the proper pouring temperature is paramount when using the plaster process.[12]

Foundry workers likely added zinc in small amounts or omitted it entirely from the alloy for plaster mold casting in order to keep the pouring temperature within that specific range. This would not have been as much of a concern with sand casting, where we see a much greater proportion of zinc, allowing for a cheaper alloy. The lower proportion of zinc also offers an explanation for the three typical alloys we see in Proctor’s Gorham castings: an alloy already melted down for plaster mold casting could be repurposed for sand casting to save time and money, but the reverse could not be done with an alloy already melted down for sand casting, because it would have contained too much zinc to achieve a proper pouring temperature for a plaster mold casting.

Another conclusion we can draw from analysis of these sculptures is that Gorham preferred one of its standard alloy formulations for its metal patterns. All of the metal patterns examined in this study were sand-cast, the majority with Gorham’s standard sand-casting formulation of more zinc and less tin. The foundry preferred this alloy formulation probably because it was strong and comparatively cheap, using less expensive zinc to harden the copper alloy. Gorham’s metal patterns were cast in parts and were not originally meant to be finished sculptures (though many were eventually assembled, patinated, and sold during times of financial stress). The founders’ priorities while casting patterns would have been to obtain a detailed casting and to create a durable surface that would hold up to multiple reproductions.

Roman Bronze Works

During the nineteenth century, the art of lost-wax casting was a mystery to American founders. The key innovation of this method is the flexible glue mold, as distinguished from sand casting’s rigid sand mold. During lost-wax casting, the founder places the plaster model into a container and pours gelatin or glue into it, allowing the gelatin or glue to capture a negative impression of the model. The flexible mold can then be separated from the model. Next the founder applies a layer of melted wax to the interior of the glue mold and pours a core of investment material inside. Then he removes the glue mold and attaches wax runners and gates to the wax positive to allow the molten bronze to flow into the mold. He surrounds the wax positive with an outer mold made from investment material similar to the core. The mold is then fired, allowing the investment to harden and the wax to melt and run out the bottom, leaving a negative space for the molten bronze. The founder then pours molten bronze into the mold and lets it cool. Finally, the sculpture is chased and patinated.

Lost-wax casting was a highly sought-after technology, as the liquid glue mold could easily capture surface detail that would take a lot of work using the sand-casting technique, and foundry workers could save a great deal of time by pouring an investment core rather than meticulously shaving away a sand core to achieve an exact duplicate of the original sculpture. By the turn of the twentieth century, lost-wax casting was an established method in Europe, but the few times it was successfully attempted in America, the founders used the “French method,” which cobbled together both a glue mold and a shaved core, making the technique too laborious and time-consuming to implement on a large scale. All that changed when Ricardo Bertelli established the Roman Bronze Works in Brooklyn in 1899. Bertelli brought with him a staff of mostly Italian-trained foundry workers who were familiar with the “Italian method” of making cores.[13] Suddenly, American sculptors could have lost-wax castings made reliably and relatively quickly, and Roman Bronze Works began to attract a variety of prominent sculptors as clients.[14]

Proctor began using the Roman Bronze Works as early as 1904, and continued to use the foundry periodically throughout his career as late as 1935. Sixteen of the sculptures tested in this study are documented Roman Bronze Works castings (with a Roman Bronze Works foundry mark, an entry in Roman Bronze’s casting ledger, or other documented provenance), and all were cast using the lost-wax method.

Roman Bronze Works appears to have had a standard alloy formulation, but approximately one-third of the sculptures tested are deviations from this formulation, with either more zinc, less zinc, or less tin than the standard. These exceptions could have been special formulations for the particular sculpture or variations in practice among foundry workers, and do not correspond to any chronological patterns. Nevertheless, the sculptures cast with Roman Bronze Works’ standard alloy formulation are highly consistent.

Eugene Gargani & Sons

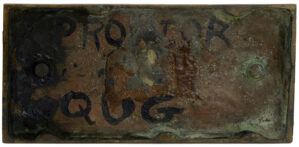

In 1927, a Roman Bronze Works foundry worker named Eugene Gargani left Bertelli’s employ to start his own lost-wax bronze foundry in Brooklyn. Gorham, who did not have the facilities for lost-wax casting and felt the pressure of Roman Bronze Works’ competition, appealed to the new foundry to begin a mutually beneficial partnership. From June 1929 to May 1934, Gorham sublet some of its jobs to Gargani to be cast using the lost-wax method. Interestingly, these sculptures cast by Gargani still bear the Gorham foundry mark.[15] There are no obvious physical markers of a Gorham-sublet Gargani casting, but they can be identified by cross-referencing the records in the Gorham casting ledgers, by examining the bases of sculptures with Gorham foundry marks for indications that they are lost-wax castings,[16] or by using XRF analysis. Another telltale sign is that some of the Gorham-sublet Gargani casts have both the Gorham foundry mark and an inscription reading “CIRE PERDUE,” which is French for “lost wax.”

Plate 12.3 — Alexander Phimister Proctor

Buckaroo, ca. 1915

Bronze. Denver Art Museum Collection; Funds from William Sr. and Dorothy Harmsen Collection by exchange, 2005.12. Photography (c) Denver Art Museum

Five of the tested Proctor bronzes are Gorham-sublet Gargani casts. Their alloy formulations are fairly consistent and extremely similar to the Roman Bronze Works alloys—the result, most likely, of Gargani’s former employment at Roman Bronze Works. [Plate 12.3]

Jno. Williams, Inc. Bronze Foundry

Jno. Williams Foundry was started in 1875 by John Williams, a former designer for Tiffany & Co. In 1905 he incorporated the foundry and changed the name from John Williams, New York, to Jno. Williams, Inc. Bronze Foundry. The year 1905 was also when Proctor began collaborating with the company. He would continue to work with it until 1911, at which time he became unsatisfied with the declining quality of its work and chose to take his business elsewhere. Ten of the sculptures tested in this study are documented Jno. Williams, Inc., castings. Jno. Williams, Inc., used the sand-cast method exclusively, and testing reveals that the company had a highly consistent alloy formulation, with more zinc and less tin than was standard for either Gorham or Roman Bronze Works.

Other Foundries

Proctor employed a variety of other foundries throughout his career. In this study, we’ve tested bronzes cast by A. Bruno in Rome, Italy; Batardy in Brussels, Belgium; the Henry-Bonnard Bronze Company in New York; Petermann in Brussels, Belgium; Pompeian Bronze Works in New York; Thiebault in Paris, France; Tiffany in Queens, New York; and Verbeyst in Brussels, Belgium. Because we have only tested one or two sculptures from each of these foundries, it is difficult to draw conclusions about the alloy formulations they used.

Identified Bronzes

Using a combination of visual inspection of the undersides of bases, comparison of the elemental data, and archival research, we have identified the foundries of thirteen bronze sculptures whose casting history was heretofore unknown. We identified five as cast by Roman Bronze Works, two by Pompeian Bronze Works, and six by Jno. Williams, Inc., Foundry. The following is an example of the process we have used to identify previously unknown foundries.

Plate 12.4 — Alexander Phimister Proctor

Indian Warrior, 1900 – 1902

Bronze, 38 5/8 in. (height). Buffalo Bill Center of the West, Cody, Wyoming. Gift of A. Phimister Proctor Museum with special thanks to Sandy and Sally Church. 4.08.2

We tested ten of Proctor’s large Indian Warrior sculptures. [Plate 12.4]

Two of those (the castings belonging to the National Gallery of Canada and the R. W. Norton Art Gallery) [Plate 12.5] have clear foundry marks indicating that they were cast by Jno. Williams, Inc., Foundry. As Peter Hassrick explains earlier in this book, Jno. Williams, Inc., Foundry used a characteristic style of underpinning that matches three other castings with no foundry mark, those belonging to the Amon Carter Museum, the Portland Art Museum, and the Seattle Art Museum. [Plate 12.6]

As noted earlier, Jno. Williams, Inc., Foundry’s alloy formulation was extremely consistent. According to our analysis, the copper-to-zinc photon ratios and the copper-to-tin photon ratios for the castings held by the Amon Carter Museum, Portland Art Museum, and Seattle Art Museum all fall within the observed range for Jno. Williams, Inc., Foundry. We therefore determined that these three unmarked castings were done by Jno. Williams, Inc., Foundry.

Plate 12.5 — Alexander Phimister Proctor

Indian Warrior (Jno. Williams, detail – underside), ca. 1895

Bronze. Amon Carter Museum of American Art, Fort Worth, Texas. 2002.5

Plate 12.6 — Alexander Phimister Proctor

Indian on Horseback (Indian Warrior) (Jno. Williams, detail – underside), 1898

Bronze. Portland Art Museum, Portland, Oregon. Gift of Mrs. A.L. Mills, Mrs. T.H. Bartlett, Henrietta E. Failing, Mary Forbush Failing, Mrs. H.C. Cabell, Charles Francis Adams, John C. Ainsworth, William D. Cartwright, and T.B. Wilcox. 11.2

Conclusions

The method outlined above for identifying elemental presences, utilizing the ratios of key elements, and comparing relative elemental concentrations using XRF analysis has revealed key patterns among Proctor’s foundries. This information, coupled with visual analysis and historical research, has helped us identify the foundries that cast some of Proctor’s bronzes with previously unknown provenance histories. As our data pool continues to grow, we will be able to recognize additional patterns that will lead to further discoveries about Proctor and his relationship with his foundries.

We will continue our testing to gather more information on the foundries underrepresented in this study and perhaps new ones for which we do not have any data yet. We will also expand our data pool to include bronzes cast by Proctor’s contemporaries who were using the same foundries, and will publish a comprehensive scientific review of our findings.[17]

[1] A bronze sculpture’s patina is the layer on the outside of the sculpture that provides its color and finish. A patina is a chemical reaction that can happen naturally as the elements in a bronze alloy interact with their surroundings, and also intentionally as part of the casting process.

[2] See Janis C. Conner, “Introduction to Cast Comparisons,” in Captured Motion: The Sculpture of Harriet Whitney Frishmuth; A Catalogue of Works, by Harriet W. Frishmuth, Janis C. Conner, Leah R. Lehmbeck, Thayer Tolles, and Jerry L. Thompson (New York: Hohmann Holdings, 2006), 101–25.

[3] XRF is a nondestructive analytical technique frequently used to determine the elemental composition of cultural heritage objects.

[4] Of the 122 lifetime castings analyzed, 29 were tested at the Buffalo Bill Center of the West in July 2016 with the same instrument. The remainder of the sculptures were tested between January 2014 and August 2016 using approximately twenty-five different instruments. All of the instruments were Bruker Tracer III-SD XRF spectrometers with the same tubes and detectors, and all of the testing was done at 40 kV and 11.60 µA using the yellow filter.

[5] We are expressing the data in unitless photon ratios. Absolute quantitative analysis is not possible or appropriate for patinated bronzes, because the alloy of a bronze sculpture is nonuniform in both depth and relative location in the bronze. Instead, XRF analysis relies on detailed analysis of a bronze sculpture’s raw photon spectra using Bayesian deconvolution and subsequent elemental presence analysis and comparison of the ratio of photons gathered from the elements present. This ratio is directly proportional to the elemental concentrations. Thus, this study utilized the ratio of the net number of photons from each element, producing an accurate unitless quantity independent of everything but the absolute ratio of those two elements. Because of this accuracy we can directly relate that ratio from every bronze to every other bronze. This relationship allows us to identify particular characteristics and patterns accurately and observe elemental trends among foundries. For more information, see Lee Drake, “XRF User Guide,” www.xrf.guru (accessed October 10, 2016).

[6] For more information on the Gorham Co. Founders Bronze Division, see Janis Conner, “Harriet Whitney Frishmuth and Her Foundries,” in Captured Motion, 52–99.

[7] For excellent illustrated descriptions of both the lost-wax and sand-casting techniques, see Michael E. Shapiro, Bronze Casting and American Sculpture, 1850–1900 (Newark: University of Delaware Press, 1985), and Malvina Hoffman, Sculpture Inside and Out (New York: W.W. Norton & Co., 1939). For a photographic walkthrough of the lost-wax casting process, see Harry Jackson, Lost Wax Bronze Casting: A Photographic Essay on This Antique and Venerable Art (Flagstaff, AZ: Northland Press, 1972). For an incredible visual of Proctor himself casting his monumental statue The Rough Rider using the lost-wax method, see The Metropolitan Museum of Art, The Making of a Bronze Statue, http://www.metmuseum.org/metmedia/video/collections/aw/making-of-a-bronze-statue, accessed December 5, 2016.

[8] The authors thank Paul Cavanagh, owner of Paul King Foundry, Johnston, Rhode Island, for describing the differences between sand-casting and plaster mold casting, which he was able to observe as the son of one of Gorham’s silver chasers employed in the 1920s. Author’s conversation with Paul Cavanagh, August 25, 2016.

[9] For more information about the role of models in the bronze casting process, see Ann Boulton, “The Making of Matisse’s Bronzes,” in Matisse: Painter as Sculptor, by Dorothy M. Kosinski, Jay M. K. Fisher, Steven A. Nash, and Henri Matisse (Baltimore: Baltimore Museum of Art, 2007), 73–97.

[10] Gorham Manufacturing Company, Bronze Division, ledger, 3680, Amon Carter Museum of American Art (microfilmed by the Archives of American Art, Smithsonian Institution).

[11] See Robert Tyler Davis, “Bronze,” in Master Bronzes, Selected from Museums and Collections in America (Buffalo, NY: Buffalo Fine Arts Academy and Albright Art Gallery, 1937); reprinted, Long Island City, NY: General Bronze Corporation), 1.

[12] Frank Pfister, “Statuary to Electronics via Plaster Molding,” reprinted from The Foundry, Gorham Manufacturing Co. (Providence: A Penton Publication, September 1952), 144–45.

[13] The authors thank Ann Boulton, Associate Conservator at the Gilcrease Museum, for a wonderful workshop on bronze casting history and bronze sculpture examination. Interested readers can watch her tour of “Frontier to Foundry: The Making of Small Bronze Sculpture in the Gilcrease Collection,” an exhibit she curated at the Gilcrease Museum, on YouTube at https://www.youtube.com/watch?v=uuwIiVRRGQE (accessed October 15, 2016). Author’s conversation with Ann Boulton, August 16, 2016.

[14] For more information on Roman Bronze Works, see Janis Conner, “After the Model: Bessie Potter Vonnoh’s Early Bronzes and Founders,” in Bessie Potter Vonnoh: Sculptor of Women, by Julie Aronson, Bessie P. Vonnoh, and Janis C. Conner (Cincinnati: Cincinnati Art Museum, 2008): 225–47. For more information on the history of lost-wax casting in the United States, see Shapiro, Bronze Casting and American Sculpture.

[15] For more information on Gorham’s partnership with Gargani, see Conner, “Harriet Whitney Frishmuth and Her Foundries,” 73–76.

[16] For more detail, see Conner, “Introduction to Cast Comparisons.”

[17] The authors wish to express their deepest gratitude to Phimister Proctor “Sandy” Church for his support and knowledge throughout the research process, and to Perrine Le Saux, Vanessa Ocaña-Mayor, Nicole Schmidt, and Michael Tusay for their help with the testing and analysis. Many thanks are also owed to Ann Boulton, Kate Gallows, and Sarah Gilcrease at the Gilcrease Museum; Jon Frembling, Rachel Panella, Sam Duncan, Jodie Utter, Fernanda Valverde, and Stacey Kelly at the Amon Carter Museum; Arlen Heginbotham at the J. Paul Getty Museum; Dr. Lisha Glinsman at the National Gallery of Art; Lee Drake at Bruker Elemental; Paul Cavanagh at Paul King Foundry; and Mark Ostrander at Conner·Rosencranz.